Our highly qualified personnel and state of the art processing methods ensure that Öztürk Endüstriyel's tool making division is both professionally and technically best-equipped. We therefore provide reliable and precisely fitting injection moulds based on our customers' specifications. Businesses who expect cost-optimised tool making according to highest standards will find in us the adequate partner.

Any metal processing requirements will be carried out by our tool making department's CAM & CNC personnel. Process-capable certified tools need to undergo monitored test runs before they are approved to be used in our injection production lines.

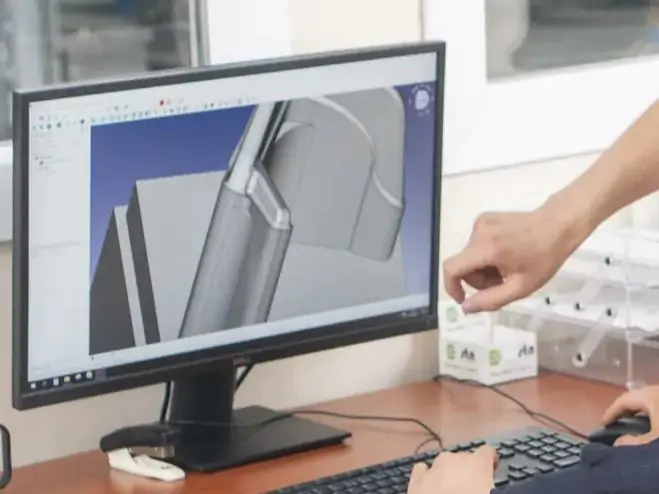

Upon request of our customers, we also carry out the part/tool engineering and deliver both these samples and their tool. Required processes such as industrial design or surface modelling are likewise done by our experienced team.

Your mould design will be analysed in depth by our design team to determine the most suitable production parameters required for serial plastic injection moulding.